-

Leading builders of Modular Homes in NSW, VIC, & SA

-

-

Leading builders of Modular Homes in NSW, VIC, & SA

Throughout 2021 and into the start of 2022, the knock-on effects of the Covid-19 pandemic were still being felt by the construction industry. With people making lifestyle and living changes, and work requirements changing for many of us, the industry saw demand for homes recover quickly, but has still been hampered by disruption in supply chains and lack of materials causing widespread delays and price rises in projects across Australia. Added to this we have seen national and international incidents with flooding in Australia and the developing situation in Ukraine placing more uncertainty on the market and leading to unpredictability in material costs.

On top of this many builders are seeing huge increases in demand for work but are struggling to get the materials they need to complete jobs as they and suppliers have worked through their stockpiles of materials or have seen them damaged by the recent flooding. Where builders have managed to source materials and take on new jobs, we have inevitably seen labour costs and material costs passed on to those building new homes.

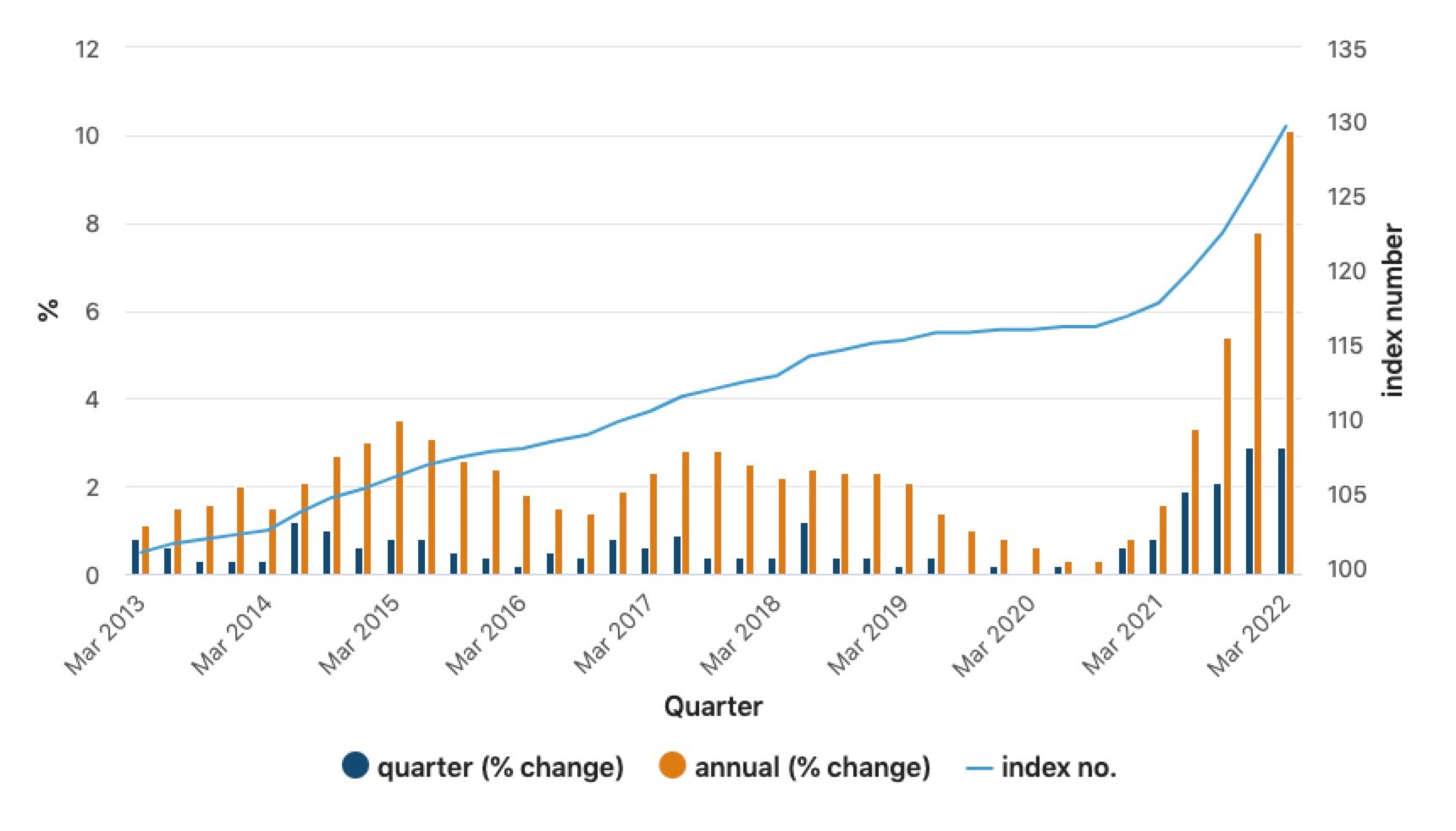

According to the ABS, building construction prices grew by 4.3% in the last quarter and house building costs increased by up to 17.3% over the last 12 months - the largest annual increase since the series began:

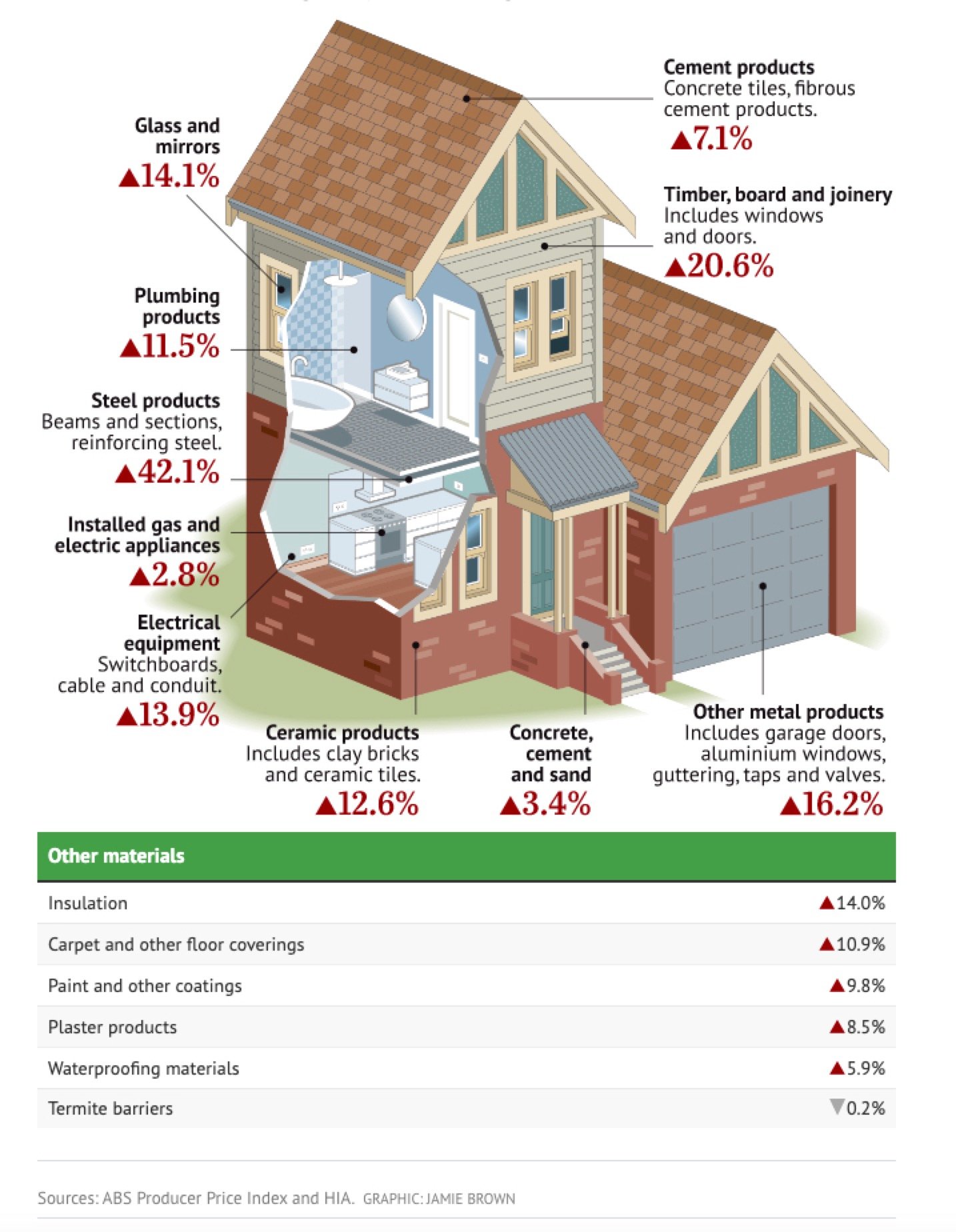

On top of all this, we've seen increases in prices for almost all materials needed for home building - and stockpiles have almost been used up by many suppliers. The Age recently ran an article looking into these increases in material prices and how almost every building material is affecting the cost of building a home:

We take a look at what this means for the industry, and also how we are adjusting to be able to continue to deliver homes in these trying times:

Pricing

Where there is a supply and demand issue, pricing inevitably goes up. Whilst we do our best to anticipate material price changes for our clients and plan accordingly, the unprecedented global demand on materials has caused shortages not just in Australia, but around the world. This means that we’ve seen prices soar by as much as 80% over the past few years on many of our key structural materials including timber and steel. As with any business, we’ve absorbed what we can however our prices have had to rise to reflect the increased cost of materials.

These pricing and supply issues are affecting the construction industry as a whole in every country – increased demand for build and difficulties in sourcing and supply of these materials have led to price rises across every aspect of construction, from labour to materials.

Time frames & Schedules

Thankfully for our clients, as an innovative modular builder we are a manufacturing facility, so we’ve been able to continue building with significantly less disruption than many of our traditional construction counterparts, however we are still seeing some knock-on effects caused by reduced output from our suppliers.

Our clients should prepare for slightly longer timelines when building with Swanbuild than usually expected, but our two plants are buzzing with activity, so we are in a better position than many people building in Victoria, whose builds have come to a complete stand-still. We are still able to build homes at a good rate and are confident that this will only improve as the situation within the industry does too.

The demand for lifestyle focussed regional and rural properties is also going through the roof, and this coupled with the increased demand for housing from the Government’s HomeBuilder Grant, many builders across Australia have filled their schedules and are struggling to deliver within their usual timelines.

Here at Swanbuild, with the opening of our Bendigo plant, we’ve effectively been able to double our production capacity – this means that although your start date may be later than you might have hoped, we’re often able to schedule in your build much sooner than with other builders.

Here at Swanbuild, with the opening of our Bendigo plant, we’ve effectively been able to double our production capacity – this means that although your start date may be later than you might have hoped, we’re often able to schedule in your build much sooner than with other builders.

Our factory production process enables us to plan, forecast, order and store materials for your homes much further ahead than many traditional builders, who must order stock to site ahead of time and would likely see materials go missing.

Flexibility

To help reduce time frames, an element of flexibility can be helpful - for instance if one of your selections has a lengthy lead time before it becomes available, we can recommend an available alternative that will still suit your vision, in order to avoid delays in waiting for products to arrive. While we certainly want you to get the finish you want, this flexibility means we can fit products and materials that are in stock or available quickly, which will reduce the time needed to complete your home.

Although sometimes your first choice on finishes might be unavailable, those that are flexible have seen reduced delays on build times. Of course, we work closely with all our clients and will always let you know if choices and finishes might pose issues with timings, and we will work through this with you. Being a relatively small family-owned company, relationships are paramount to us and you’ll have us to keep you informed and guide you every step of the way.

Whilst your dream home may now cost a little more to build, for many of our clients’ priorities have also changed in the past 18 months. With so many of us confined in lockdowns, the focus on work/life balance and getting a lifestyle to suit in the changing face of the world has demonstrated that we should seek out our dreams and that a moving to your dream location and getting the home you’ve always wanted is a great investment.

At Swanbuild, we continue to strive to provide the best service and homes for our clients. These changes in the industry are unfortunately unavoidable at the moment, but we are doing everything we can to help our clients achieve their dream move. If you have any questions on this or anything else, please get in touch!